What is MSC Apex Generative Design?

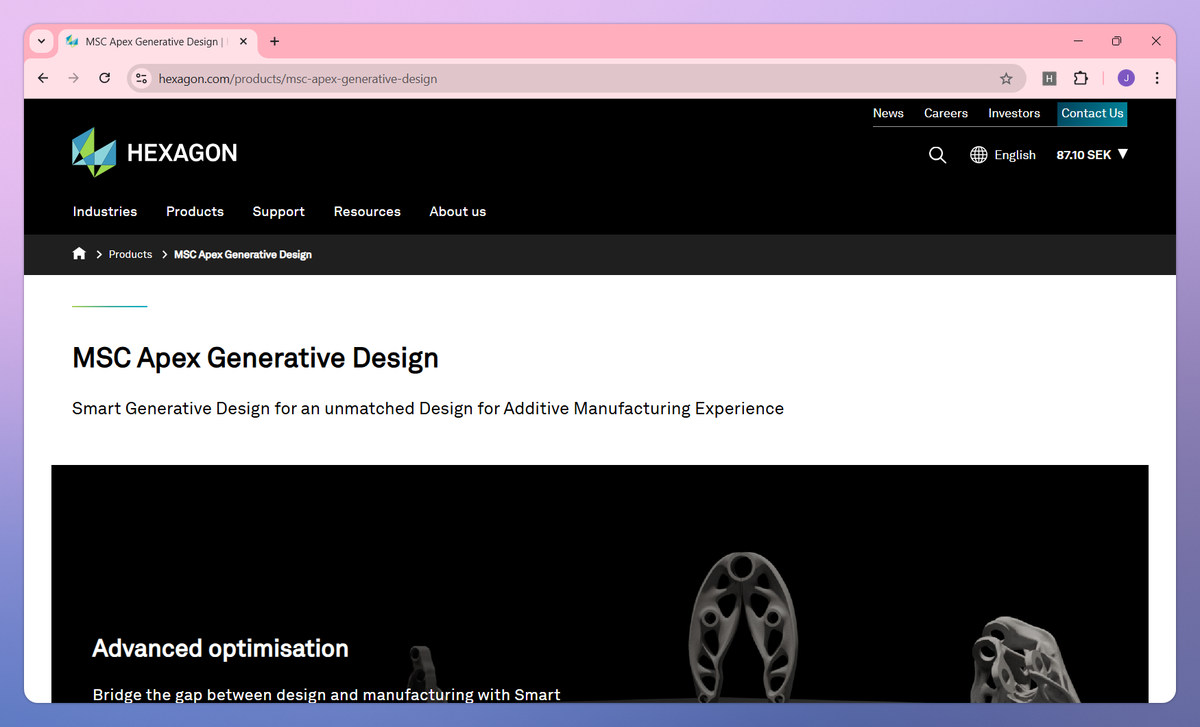

MSC Apex Generative Design is a smart optimization tool that bridges the gap between design and additive manufacturing for engineers. It automatically creates stress-optimized structures with bionic-shaped designs, generates error-free meshes, and directly exports CAD files without manual rework for immediate 3D printing applications.

What sets MSC Apex Generative Design apart?

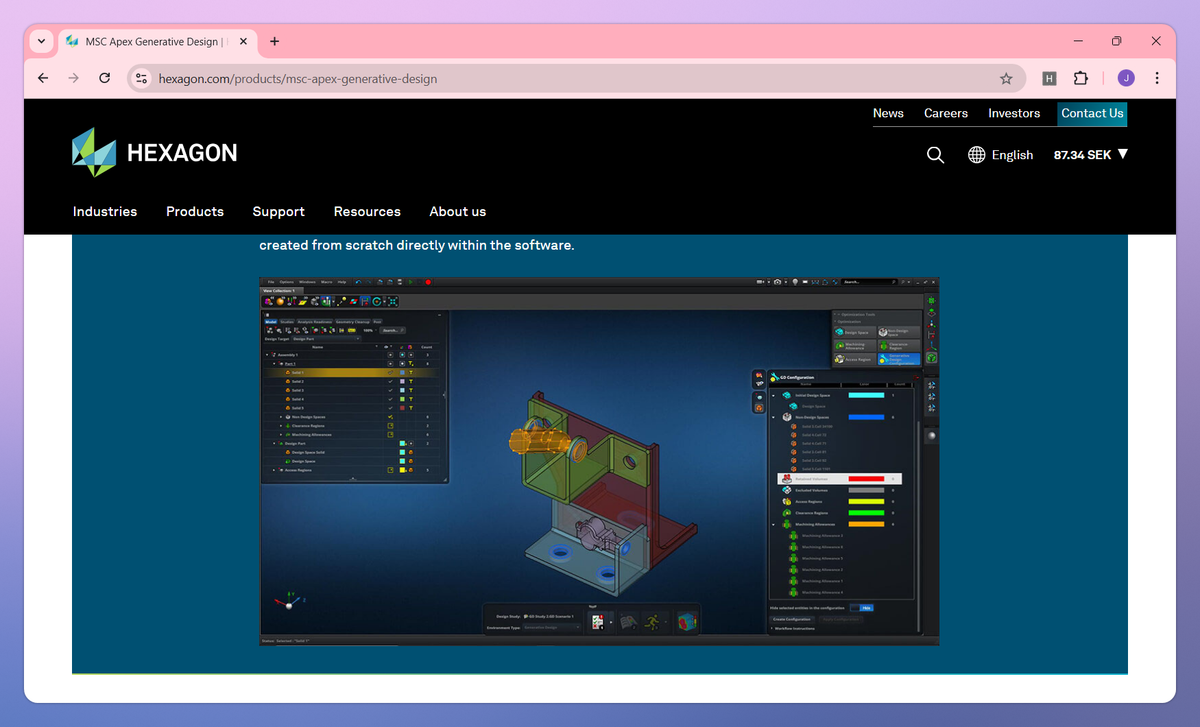

MSC Apex Generative Design differentiates itself with a stress-based optimization approach that delivers lightweight structures with homogenous stress distribution, making it ideal for aerospace and automotive engineers working on weight reduction challenges. The tool's user-friendly interface is particularly helpful for design engineers who lack specialized optimization knowledge but need to create print-ready parts with minimal training. Its all-in-one environment eliminates the need for separate retransition software, allowing engineers to move from concept to CAD output in a single workflow.

MSC Apex Generative Design Use Cases

- Automated part optimization

- Lightweight component design

- 3D print design validation

- Engineering design automation

Who uses MSC Apex Generative Design?

Features and Benefits

- Bridge the gap between design and manufacturing with automated optimization that creates designs perfectly matched to your requirements.

Smart Generative Design

- Create bionic-shaped designs with homogenous stress distribution for enhanced part reliability and performance.

Stress-Based Optimization

- Export optimized designs directly to CAD file formats without manual rework, streamlining your design-to-manufacturing workflow.

Automated CAD Integration

- Generate defect-free surfaces automatically with fine, smooth transitions that ensure high quality for every design.

Intelligent Smoothing

- Reduce optimization time significantly through automation and advanced algorithms for faster, cost-efficient design development.

Time-Efficient Process