What is Solid Edge Generative Design?

Solid Edge Generative Design is an optimization tool that creates lighter components while maintaining structural integrity through topology optimization. It helps engineers and product designers reduce material usage, replace multiple assemblies with single components, and develop parts ready for 3D printing without compromising strength or functionality.

What sets Solid Edge Generative Design apart?

Solid Edge Generative Design sets itself apart with simultaneous testing of multiple weight targets, load cases, and constraint scenarios, giving engineers complete control over design parameters and outcomes. The tool's direct integration with Convergent Modeling and Synchronous Technology is valuable for product designers who need to modify optimized components without waiting for mesh-to-b-rep conversions. It enables manufacturers to develop distinctive product aesthetics and market differentiation through organic, mathematically-optimized structures.

Solid Edge Generative Design Use Cases

- Component weight optimization

- 3D printing design automation

- Structural topology optimization

- Manufacturing cost reduction

Who uses Solid Edge Generative Design?

Features and Benefits

- Reduces both weight and material usage while maintaining structural integrity, leading to more efficient component designs.

Topology Optimization

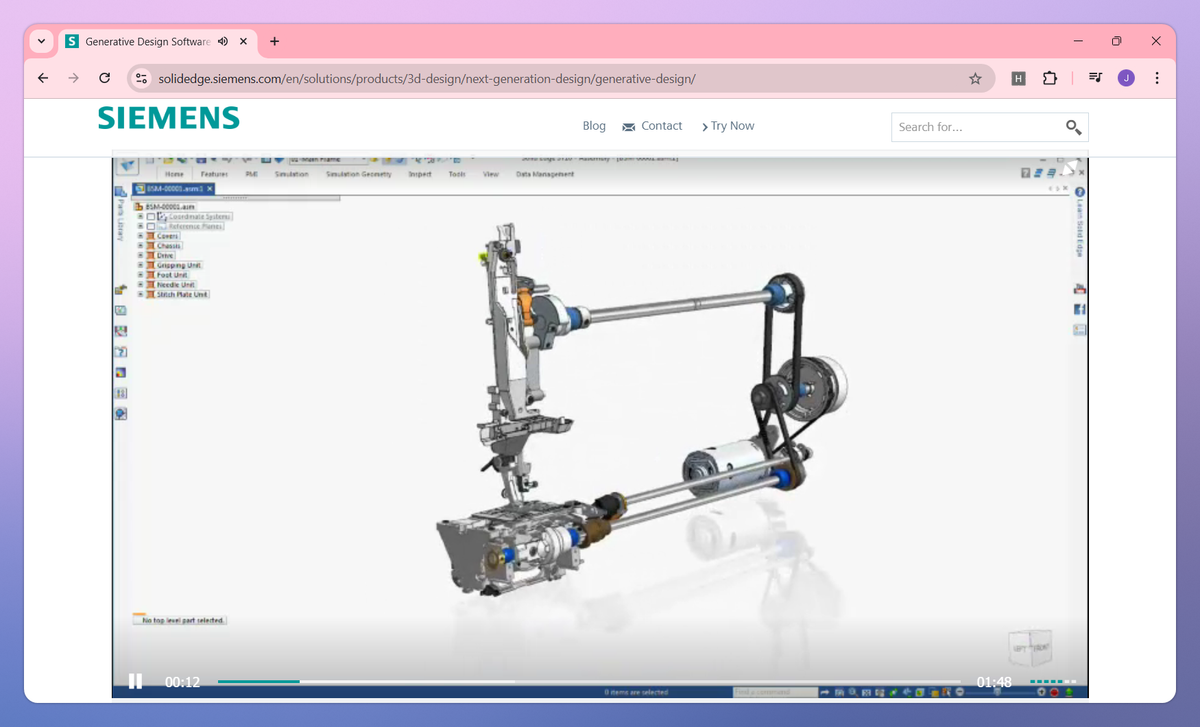

- Replaces small assemblies with single components, reducing manufacturing costs and bill-of-materials complexity.

Assembly Simplification

- Computes optimized geometric solutions based on specific materials, design spaces, loads, and constraints to meet exact requirements.

Customized Parameters

- Creates parts compatible with high-resolution 3D printers, supporting complex shapes for faster production and time-to-market.

3D Printing Ready

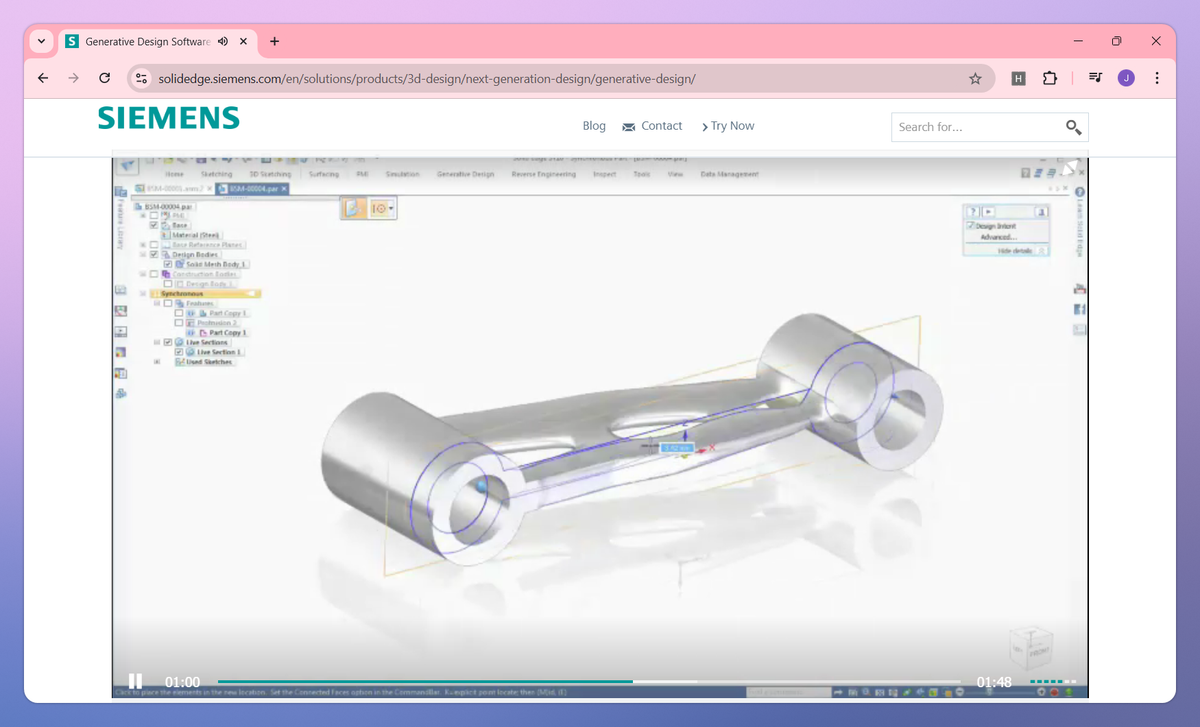

- Seamlessly works with Convergent Modeling and Synchronous Technology to further refine and evolve generated designs.

Design Integration

Solid Edge Generative Design Pros and Cons

Synchronous technology enables quick and intuitive design modifications without complex pre-planning

Exceptional sheet metal design capabilities streamline manufacturing workflows

Powerful simulation tools help optimize designs before physical prototyping

User-friendly interface with customizable menus increases productivity

Performance slows significantly when handling large complex assemblies

Steeper learning curve compared to competing CAD software

Limited community resources and training materials available online

Occasional crashes and stability issues during intensive tasks